Energisation

" Energisation" refers to progressive power supply for the transformer

up to voltage and nominal load (in the specific operating site).

This phase covers the first three months of operational life of the transformer, during which the conformity of the properties of the insulating oil and electrical and functional performance are monitored. The first hours of operation of the machine are particularly important, after which monitoring of the trend of the main parameters is continued at set intervals (in the first 7 days, 15 days, 30 days, 90 days) based on the type of transformer.

Warning. Typically, "energisation" is used in reference to a new transformer, however the same term can also refer to the re-energisation of a transformer following major electromechanical repairs or servicing or even after a long out-of-service period.

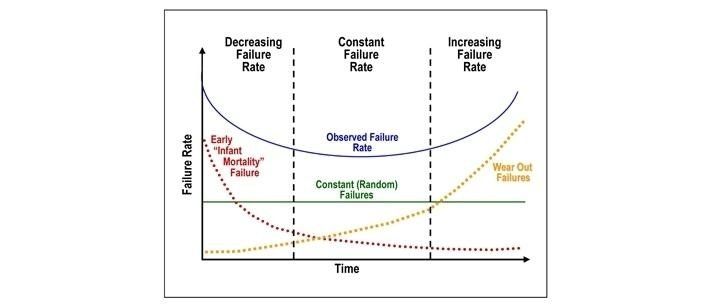

Critical problems may arise in the "energisation" phase, for example problems related to the design and construction of the transformer, to installation and to filling. This phase is characterised by a significant failure rate (infantile failures, first sector of the graph) that gradually decrease according to the bathtub curve.

In this phase, Sea Marconi is able to support owners with supervision and maintenance of the oil-transformer system (and of its accessories).

In concrete terms, Sea Marconi performs:

- A. sampling, analysis of oil, and certification of analytical results. The type and frequency of controls vary based on the type of machine-oil and the critical problem diagnosed;

- B. diagnosis of critical problems in the oil-transformer system; In particular, the characteristic trends of certain parameters of the oil should be monitored in order to exclude typical "infantile failures";

- C. a final report suggesting appropriate corrective actions( solutions) to eliminate or mitigate the critical problems found. Particularly important corrective actions include interventions on the oil (physical treatment, selective depolarisation, and integrated treatment of the oil-transformer system) as well as electromechanical activities on the machine.

? You have received the results of the oil analysis from your provider but you need another opinion?

Contact us for assistance in interpreting the results, or for repeating the analysis.

?

Have you already scheduled a monitoring and diagnostic coverage plan during the life cycle of the transformers according to the time indicated by sector standards?

Contact us to plan activities together.

Why to choose Sea Marconi

- Sea Marconi has developed the sector's largest private database.

- We carry out accredited and state of the art analysis, meaning the ability to offer oil analysis not only through basic tests indicated in the technical standards, but also through the most current standards (e.g. corrosion problems) that may give answers to critical issues not yet published in the standards.

- Equipped with a full field kit set to obtain a first screening of the oil directly in the field (screening of PCBs, acidity and total corrosive sulfur)

Normative requirements

IEC 60422 ed. 4.0 - 2013 ->

Mineral insulating oils in electrical equipment – Supervision and maintenance guidance

IEC 60599 ed. 2.0 - 1999 ->

Mineral oil-impregnated electrical equipment in service - Guide to the interpretation of dissolved and free gases analysis