Chedcos selective depolarisation

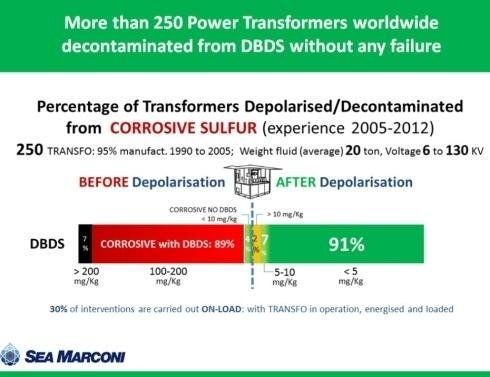

For insulating fluids that exhibit corrosive behaviour (e.g DBDS presence > 10 mg/kg), Sea Marconi has developed and patented Chedcos® selective depolarisation from corrosive sulfur, a solution that has been integrated and validated with success on the market.

Our solution is efficient, economic and definitive because it eliminates the problem by ensuring DBDS < di 10 mg/>g and functional properties in conformity with IEC 60422 Ed. 4-2012, CIGRE 378-2009 Art. 4.2.

| Total figure for equipment decontaminated from corrosive sulfur up to December 2017 |

500 |

| Total mass of oil decontaminated from corrosive sulfur up to December 2017 |

approx. 7,736 tonnes |

Chedcos® selective depolarisation uses

- a MDU(Mobile Decontamination Unit) built in-house,

- patented reagents(S/CHED®) without which the treatment would not be as effective

- a single operational method because it is carried out on-site and with closed-loop, meaning that the transformer is not emptied, not even partially

- appropriate safety procedures also for the " On-Load" mode, meaning that the transformer can be kept in service and under load for the duration of the treatment.

Chedcos® treatment makes it possible to avoid the critical logistic and operational problems of fluid replacement, which would still be contaminated with DBDS present in the residual oil of impregnated pressboards.